Electronics I Software I Decolletage I Control

VNSA SA

SINCE 1985

PORTRAIT OF THE COMPANY

The company started its activity in 1985 as specialist in the optimization of cam machines by creating systems that increase productivity and quality. They are known as Variocam, VarioStop, Vario 3000, WinVario and MultiVario. Large companies like Tornos have equipped their cam machines with VNSA systems called MS7 Vario.

These skills have enabled us to create our own ELWIN cam machines, VN7 and VNL numerical control machines and MILCAM cam milling machines.

With its own cam and CNC machines, VNSA SA then perfected their skills in the machining of high precision parts for the connector, watch, aeronautic and medical industries.

In 2008 the certification ISO 9001 confirmed a quality know-how that was already applied. This validation has only strengthened the company's philosophy of customer satisfaction and quality of services and products.

ELECTRONICS

FLEXIBLE I INTUITIVE I INNOVATIVE

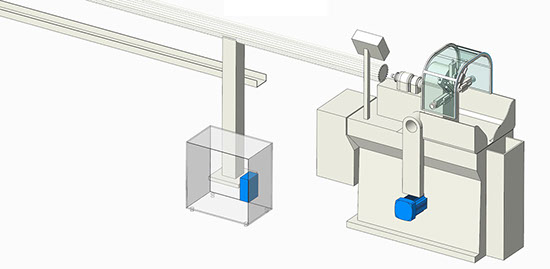

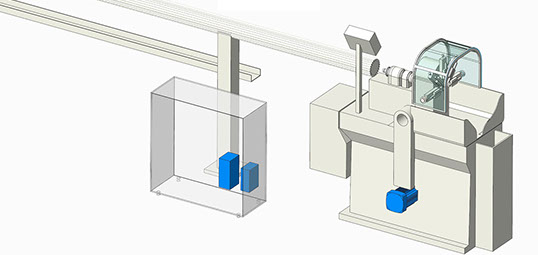

Thanks to new technologies and IT developments, the MultiVario is version 4.0 of the VarioCam and VarioStop. This new system brings added value to cam-controlled to

cam machines by increasing output and reducing costs. It is available in four different models and can be modified at any time.

MultiVario simple

MultiVario simple

Motor on the camshaft allowing to vary his speed, parts counter, adjustment of the cam errors by programming, parts counter, moving the first part away from the bar and use of the input/output (e.g. control of the presence of a bit or others)

• Increasing production rate

• Improving machining quality

• Dissociate the speed of the headstock (spindle) and the tools

• Easy to use touch screen

MultiRemote

• Information transmission (up and down)

• Remote setting

• Management of the carousel

• Management of the bar feeder

• Heating mode

• Move the first part away from the bar

• Use of input / output

• Parts counter

• Programmed stop with light column

MultiVario with converter

Same option as the MultiVario simple

Variation of the headstock (spindle) speed by a frequency converter

• Increasing speed ++.

• Reducing tool wear

• Increasing machine autonomy

MultiVario stop

Same option as MultiVario simple

Servomotor to stop the headstock

• Increasing speed +++

• Reducing tool wear

• Controlled stop

MultiVario stop with axis (es)

Same option as MultiVario stop

Synchronization of additional axis such as polygon, 20 QB, 20 BB, etc.

• Production of cut off parts

• Increasing the machining complexity

Software

DEVELOPMENT I RETROFIT I INDUSTRY 4.0

Dues to experience and knowledge of reusing existing machineries, we find uncompromising solutions for retrofitting your Swiss type turning machines. With our

technical support we enable you to move to Industry 4.0. Our developers are available for your future projects.

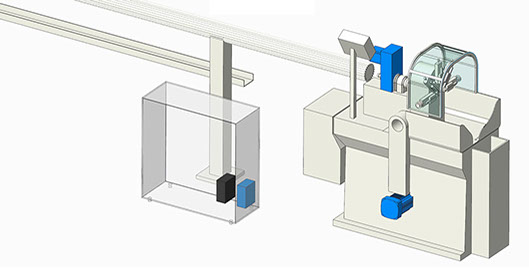

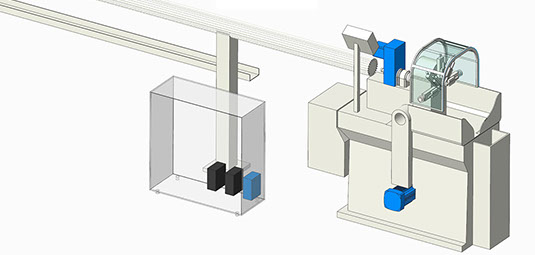

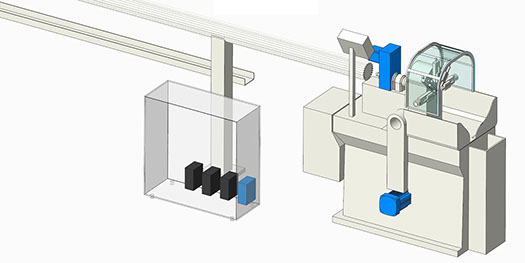

DEcolletage

EFFICIENCY I KNOW-HOW I PRECISION

The Swiss type turning department, with its 40 cam and CNC machines, produce high precision parts for demanding customers from all over the world. With the meticulous work of our employees, we are able to guarantee the highest quality and maintain our competitiveness.

Industrial markets

• Telecom Industry

• Watch Industry

• Aeronautic Industry

• Medical Industry

Precision

• Part size 0.1 mm to 20 mm

• Batch size: from prototype to millions

• Tolerance of +/- 1μ

Material

• Stainless steel, old silver, copper, brass, titanium, aluminum, various plastics, etc...

Competences

• Precision turning and milling

• Assembly

• Manufacturing of machine tools

• Development of software and controls

Finishing & treatment

• Various surface treatments on request

• Various heat treatments on request

• 100% control

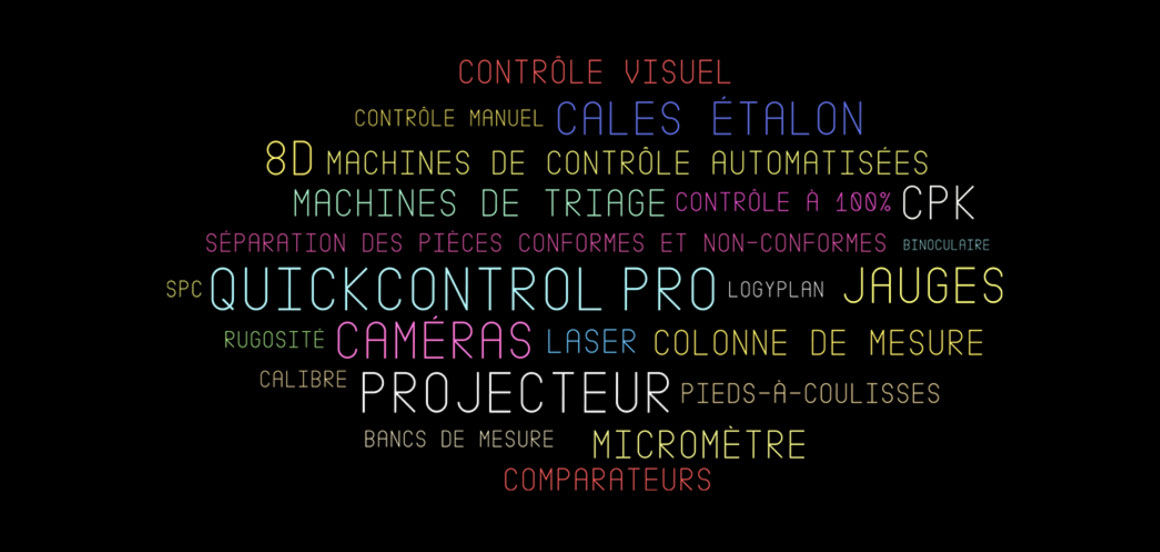

Control

RIGOR I RELIABILITY I QUALITY

The professional and rigorous control department allows us to meet all the quality and documentation requirements of our customers.

EMPLOYMENT

CAREER I CHALLENGE I TRAINING

Currently we have no vacancies. We think speculative applications are great.

CONTACT

VNSA SA I Rue de l’Ecluse 35 I 2740 Moutier I swiss I Tél. +41 32 494 60 60 I E-mail: info@vnsa.ch

WHERE TO FIND US

OUR PARTNERS

prospectus

VSBP Holding

50 Serangoon North Ave 4

#07-05 First Centre

Singapore 555856

Ph: +65 98259690

E-mail: enquiries@vsbpmachine.com

© vnsa.ch